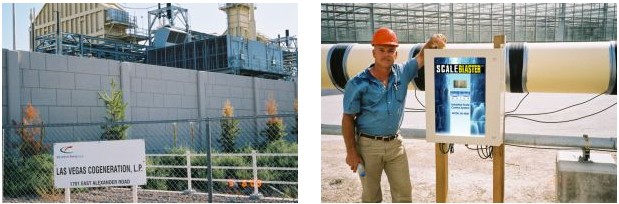

Case Study: Las Vegas Cogeneration Plant

Overview

This Las Vegas Cogeneration Plant was a 238-megawatt power plant that uses the warm water it produced to heat a massive 12-acre greenhouse that produced 40,000 lbs. of tomatoes a day.

Challenges

Due to the nature of heating water in an extremely hard water area, major scaling in the heating pipes were taking place. The expense of using chemicals to remove the limescale, not to mention downtime and labor were a costly adventure. Producing alterative green energy is costly as it is, and this only added to the monumental expenses

to produce heat.

Solution

The very first ScaleBlaster industrial model – a SB-4000 was installed on the pipeline. The pipe was a twenty (20) inch steel pipe – the first time a ScaleBlaster was used on magnetic pipe of that size.

Installed

May, 2003

Outcome

ScaleBlaster was a total success. This was one of ScaleBlaster’s greatest success stories ever. The scaling issues dramatically stopped forming and were no longer a serious and costly issue. Unfortunately, politics caused the state to shut down this cogeneration plant a few years ago. ScaleBlaster’s savings were not enough to justify the costly adventure of using this type of green technology in power generation.