Case Study: Mexican Geothermal Steam Wells

Overview

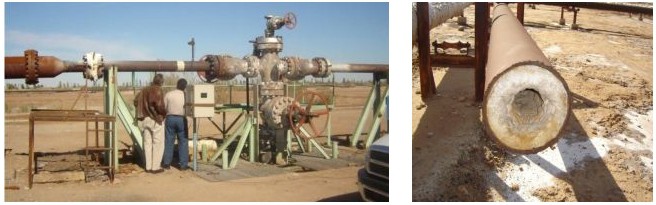

In Mexico, there are many “hot spots” or thermal pockets inside the earth where they drill deep into the ground. Heat from a fuel source (in geothermal’s case, the earth’s core) is used to heat water or another working fluid. The working fluid is then used to turn a turbine of a generator, thereby producing electricity.

Challenges

As steam comes out a 6” or larger pipes, the orifices were getting restricted in the pipes by calcifying with calcium and struvite. The expense of breaking down the system to clean the rock-hard substances is astronomical. The downtime was more troublesome as the geothermal steam wells are constantly moving to new locations. This cleaning usually had to be done often and replacement of capital equipment was frequent also. Scale included three types of silica and would grow one inch every 15 days.

Solution

Various SB-600s, SB-650s, SB-1400s and SB-2000s have been installed.

Installed

2001 to current.

Outcome

The scaling issues have been solved, saving the operator’s millions of dollars.