Utilizing ScaleBlaster in Large Water Systems

Maintaining process water treatment along with boiler treatment and cooling tower water treatment is extremely important, especially those of municipal water treatment.

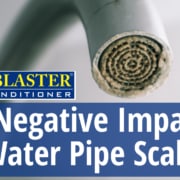

A boiler is a closed vessel in which water or other fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking and sanitation. The pressure vessel of a boiler is usually made of steel or alloy steel or historically of wrought iron. Historically, boilers were a source of many serious injuries and property destruction due to poorly understood engineering principles. When water is converted to steam it expand to over 1,000 times its original volume and travel down steam pipe at a great speed. Steam is a great way of moving energy and heat around a site from a central boiler house to where it is needed, but without the right boiler feed water treatment, a steam-raising plant will suffer from scale formation and corrosion. Water heater maintenance and heating exchanger maintenance is important and ScaleBlaster is the no-maintenance, no chemical solution.

Cooling tower water treatment and chiller water treatment are important, too. In cooling water scale, deposits will need to be removed to make the equipment much more efficient. Under certain conditions, a biofilm of micro-organisms such as bacteria, fungi and algae can grow very rapidly in the cooling water and can reduce the heat transfer efficiency of the cool tower. ScaleBlaster will control all of these issues while saving the company without wasting a lot of water. Waste water treatment is another application where ScaleBlaster is a great investment for any company.